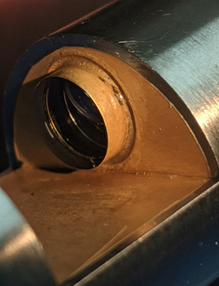

Direct insertion probes and process spectroscopy are a common PAT tool. A successful PAT implementation requires that the probe be hermetically sealed to prevent leaks and maintain proper operation. The optics on the process side of the probe can either be sealed with an o-ring or a metal alloy braze. The choice of sealing technology depends on the application and chemical compatibility. The image below shows the path piece of an o-ring sealed and a brazed sealed direct insertion probe.

O-ring Sealed FT-NIR Probe

Metal Braze Sealed FT-NIR Probe

Choosing Between the O-ring vs Braze Seal for Direct Insertion Probes

The primary deciding factor between an o-ring and metal braze seal is chemical and process compatibility. Gold Alloy brazed probes are susceptible to attack by process streams containing strong acids, bases, or cyanides. Whereas o-rings require periodic replacement and are susceptible to premature failure due to thermal cycling. Whenever possible a brazed direct insertion probe is recommended due to its longer service life.

The same considerations apply for both UV-VIS and FT-NIR direction insertion probes.

Choosing an O-Ring Material to Seal a Direct Insertion Probe

- For many applications Viton® o-rings are acceptable

- When in doubt consult with the manufacture, many offer Kalrez® 4079, Kalrez® 1050, and Kalrez® 6375

- For added safety a Kalrez® 6375 o-ring kit is a good option

- For additional information on o-ring selection please see the Elastomers Chemical Resistance Guide and Kalrez® Application Guide by Dupont. https://www.dupont.com/knowledge/elastomer-chemical-resistance-guide.html

Choosing a Braze Material to Seal a Direct Insertion Probe

Vendors such as Guided Wave Inc. specialize in making braze sealed FT-NIR and UV-VIS direct insertion probes. They offer two different braze materials which can be selected based on process conditions.

- GEORO Braze – The standard seal uses a gold based alloy to provide a seal around the optics and prevent the process from penetrating into the internal optics of the insertion probe.

- NIORO Braze – Developed specifically for high temperature, low viscosity processes, this nickel based alloy provides a vacuum-tight seal with a small grain boundary. The small grain size reduces the possibility of inclusions allowing the process to leak into the internal optics.

Custom FT-NIR and UV-VIS Probe Designs Available

Guided Wave offers a variety of probes, flow cells and fiber optic cables that meet the harsh demands of the process environment. Their probes are compatible with many fiber optic FT-NIR, Dispersive NIR, or UV-VIS based analyzers.

Probes and flow cells can be optimized for the UV, visible, or NIR spectral regions or supplied with custom fiber diameters and connectors to match your optical requirements. However, if they do not have a probe or flow cell that meets your precise need, Guided Wave has the experience and expertise to design a custom solution for your particular process installation. Please contact Guided Wave with your requirements. A flange seal can be added to the direct insertion probe upon request. All purchases of Flanged SST Probes require a customer signoff drawing to confirm the location and dimensions of the flange.