Single-Sided Transmission (SST) Probes

The most common probe used for PAT it the Single-Sided Transmission (SST) probe. It has been on the market for over 25 years, and is the most widely copied probe design in the industry. Rugged and reliable, it’s ideal for continuous process monitoring applications. Easily installed in a pipe or reactor through a single access port, the SST Probe is compatible with many analyzer brands. Optional accessories make it easy to adapt the SST Probe to different kinds of process installations as well. Various types of flanges are available on the SST Probe such as, DN25 PN40, DN125 PN16, 1” Class 150 RF, 4” Class 1500, and others.

The SST Probe’s sapphire optical windows are sealed to the probe body with proprietary gold alloy brazing. These materials are unaffected by most hydrocarbons and polymers.

Single-Sided Transmission (SST) Probe Design Features

- Corrosion resistant construction

- Rugged and vibration resistant design

- Sealed against ambient moisture infiltration

- High optical throughput for low noise spectroscopy

- Probe body material 316L SS standard 304 SS – 316 SS, Hastelloy C-276, Monel, Titanium and Nickel, others available on request

- Optional flanges – DN25 PN40, DN125 PN16, 1” Class 150 RF, 4” Class 1500, and others

Single-Sided Transmission (SST) Probe Pathlengths and Operating Ranges

- Standard Pathlengths: (mm ± 0.075 mm) 2, 5, 10, 15, 20, 50 mm

- Temperature Ranges: to 300 °C

- Pressure Ranges: to 2000 psi or 138 bar

- Higher pressures are available on request

O-Ring Single-Sided Transmission Probe

For Process Sampling

For extremely corrosive processes environments, especially those containing nitric acid or cyanides the O-SST Probe is the better choice. The O-SST probe is designed to withstand harsh process attack to the gold alloy seals used in the SST probe. The body of the O-SST probe is also built from 316L stainless steel (standard, however, several other alloys are available by special order from the manufacturer). The probe’s sapphire optical windows are sealed to the probe body with polymer o-rings chosen to be compatible with your process. For assistance with choosing the best o-ring material, please consult the DuPont™ Elastomers website. The probe can be dismantled for periodic o-ring service, although its recommended this be done by the manufacturer to ensure optimum performance. On request, the O-SST can be supplied welded to an ANSI or DIN process flange. The O-SST is also sealed against ambient moisture infiltration.

O-SST Probe Design Features

- Corrosion resistant construction

- Rugged and vibration resistant design

- Sealed against ambient moisture infiltration

- High optical throughput for low noise spectroscopy

O-SST Probe Pathlengths and Operating Ranges

- Standard Pathlengths: (mm ± 0.075 mm) 1, 2, 5, 10, 15, 20, 30, 40, 50 mm (other lengths available on request)

- Temperature Ranges: 0 to 300 °C

- Pressure Ranges: to 2000 psi or 138 bar

- Higher pressures are available on request

Probe Anatomy – Sealing Method Qualifies as Secondary Seal under the ISA Standard

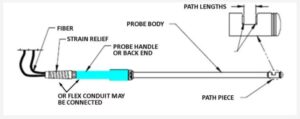

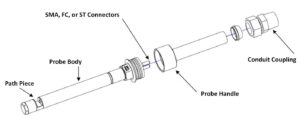

In the case of the SST Probe and the O-SST Probe (Figure 1 and 2 below), the fiber exits the probe at an SMA connector. These connectors are sealed to the probe body by either o-rings or adhesives. Both probe designs have had this seal mechanism tested to greater than 3 times the probe’s pressure rating. Thus, the sealing method qualifies as a secondary seal under the ISA standard.

Turbidity Insertion Probe

Process measurements for Haze or Turbidity (NTU) benefit from the use of a specially designed Turbidity Probe with an additional third port. The turbidity measurement detects solids breakthrough in your process while simultaneously measuring the transmission. Haze or turbidity measurement is made by a 90° back scatter method. This function requires a third optical fiber to return the scattered light to the analyzer.

For example, a 20mm pathlength Turbidity Probe is appropriate, when monitoring Saybolt color. One of the primary advantages of UV-VIS and NIR process spectroscopy is the utilization of intrinsically safe fiber optic cables to remotely locate the analyzer relative to your process.

Turbidity Probe Simple and Serviceable Design Features

- Corrosion resistant construction

- Rugged design

- O-ring process seals

- Sealed against ambient moisture infiltration

- High optical throughput for low noise spectroscopy

- Collimated beam for accurate absorbance measurements

- Vibration resistant design

- Haze or turbidity measurement is made by a 90° back scatter method. This function requires a third optical fiber to return the scattered light to the analyzer.

Turbidity Pathlengths and Operating Ranges

- Optical Pathlength: 20 mm

- Temperature Ranges: -20 to 250 (o-ring dependent)

- Pressure Ranges: 0 to 500 °C

Optional Turbidity Probe Accessories

The Turbidity probe is available with optional accessories for easy adaptation to different process installation configurations.

- Custom Flanged Probes: Facilitates direct installation of the process probe onto a T junction

- Extractor Assembly Mechanism: Facilitates installation of the process probe so that it may be cleaned without disrupting your process

- Rapid safe extraction of in-line probe from pressurized process streams

- Mounts to a gate valve via 2 inch Class 300 raised face flange

- Teflon “V” ring packing glands standard